Drip Bag Packaging Machine

For filter coffee/tea bags with ultrasonic sealing and nitrogen flushing options.

Packaging Automation Solutions

Custom-engineered VFFS Packaging Machinery, Drip Bag, and Multi-lane solutions with ±0.5g precision and 15+ years of R&D expertise.

From single Packaging machines to turnkey lines tailored for a diverse range of industries.

For filter coffee/tea bags with ultrasonic sealing and nitrogen flushing options.

Automated filling and sealing for various stand-up pouches and zipper bags.

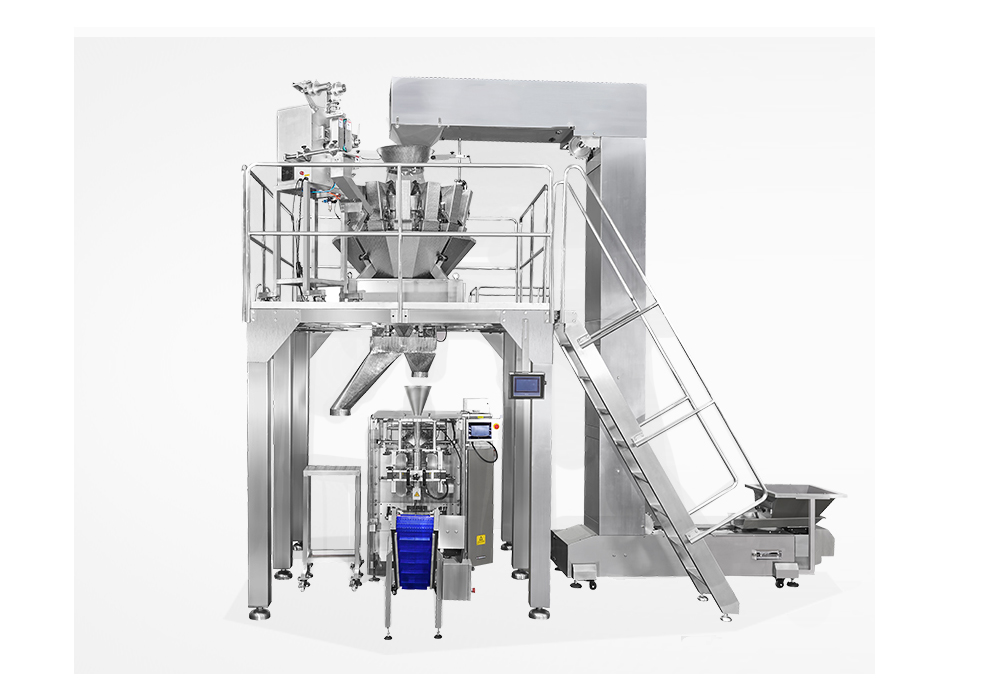

Vertical Form-Fill-Seal systems for powders, granules, and liquids at high speeds.

High-throughput solutions for stick packs and 4-side seal sachets.

Feeders, conveyors, checkweighers, and metal detectors for complete line integration.

Solve real production problems across Food & Beverage, Health, Agriculture, and Chemicals.

"From 35 to 55 bags per minute with guaranteed stability and oxygen control. Exactly what we needed."

Low speed (35 BPM), unstable performance, inconsistent freshness quality.

80E VFFS with precision weighing and advanced nitrogen flushing system.

57% faster production: From 35 to 55 BPM stable output

Guaranteed freshness: Controlled residual oxygen rate

Zero downtime worries: Consistent, reliable performance

Better ROI: Higher throughput with same labor cost

Engineered for precision, uptime, and sustainability across coffee formats.

Need a technical deep-dive with your engineers?

Pioneering the future of packaging automation with precision, quality, and sustainability at our core.

Uncompromising commitment to manufacturing the highest quality packaging machinery with rigorous testing standards.

Continuously pushing the boundaries of packaging technology with cutting-edge research and development.

Dedicated to understanding and exceeding our customers' expectations with tailored solutions and support.

Committed to environmentally responsible production processes and eco-friendly packaging solutions.

Let's discuss how our innovative solutions can meet your specific needs

Our packaging machines meet the highest international quality and safety standards, ensuring reliable performance and regulatory compliance for your production line.

European Conformity marking ensuring compliance with EU health, safety, and environmental standards.

International quality management system certification guaranteeing consistent, high-quality manufacturing.

Third-party verification by SGS, the world's leading inspection and certification company.

German technical safety certification ensuring equipment reliability and operational safety.

All contact surfaces use FDA-approved, food-safe materials meeting strict hygiene requirements.

Designed for sustainable packaging films, supporting your environmental responsibility goals.

Trusted by industry leaders worldwide. Discover how our packaging solutions transform businesses and exceed expectations.

Join hundreds of satisfied customers worldwide

Get quick answers to common questions about our packaging machinery and services.

Lead times vary depending on the machine's complexity and current production schedule. Standard machines typically have a lead time of 30-60 days, while fully customized lines may take 90-120 days. Please contact us with your specific requirements for an accurate timeline.

Yes, we offer comprehensive installation, commissioning, and training services. Our technicians can travel to your facility to ensure the machine is set up correctly and your team is fully trained on its operation and maintenance.

All our machines come with a one-year warranty on parts. We also provide lifetime technical support via phone, email, and video call. Spare parts are readily available to minimize any potential downtime.

Absolutely! We specialize in custom packaging solutions. Our engineering team can modify existing designs or create entirely new machines to meet your specific product dimensions, production volumes, and packaging materials.

Our machines are CE certified for European markets and comply with international safety standards. We also maintain ISO 9001:2015 certification for our quality management system, and all food-contact surfaces use FDA-approved materials.

Regular maintenance includes daily cleaning, weekly lubrication of moving parts, and monthly inspections of wear components. We provide detailed maintenance schedules and can offer preventive maintenance contracts to ensure optimal performance and extend machine life.

Yes, we work with trusted financing partners to offer flexible payment options including equipment leasing, installment plans, and trade-in programs. Our sales team can discuss the best financing solution for your business needs and budget.