Glossary Of Packaging Machine Terms

Product packaging is very important for the product, attractive and unique packaging design can make our product brand stand out. So How many type of product packaging using in our daily product?

First is Flexible packaging, this type it refers to a package which shape can be easily changed and fold, such as plastic film packaging, paper bag packaging.

Second is rigid packaging, such as glass bottle, metal can, and ceramic packaging.

Flexible packaging is one of the fastest growing parts of the packaging industry, so does the demand for flexible packaging machine.

Understanding some common terminology of flexible packaging machines would be great help for you choosing one packaging machine. Whether it is before or after you buy it. This article focuses on the terms commonly used in vertical packaging machine, which will be introduced one by one below.

1.PLC controller of vertical packaging machine

A superior packaging machine needs an excellent logical program to order the machine running.

The programmable logic controller (PLC) of a packaging machine, just like a computer host which uses a class of programmable memory for its internal stored programs to execute user-oriented instructions such as logical operations, sequential control, timing, counting, and arithmetic operations. Tianjin Newidea Machinery adopt world class brand like Schneider, Mitsubishi PLC for their vertical packaging machine.

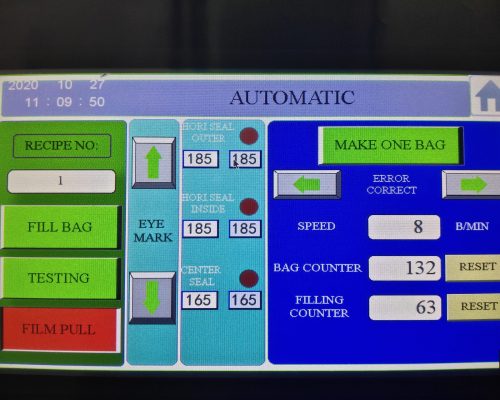

2.HMI of vertical packaging machine

Human Machine Interface, it is a touchable display screen for operation. This touch screen can display machine status (e.g. machine speed, fault conditions, etc) and is also used to directly control the machine such as start/stop machine, manual adjustment, film center tracking, parameter setting for different bag size and forms and so on.

3.Bag Forming tube and shoulder

This device is for forming different bag shapes. The flat film web will be transferred on the shoulder then along the tube till to the bottom of the forming tube. The vertical and bottom are sealed by the sealing jaws, the product dropped into the bag, then the cutters will cut the bottom, a filled bag finished. Different bag width and bag type need different bag Forming tube and shoulder.

4.Draw down belt system

Drawing down the film through the bag forming tube for making and fill next bag. With servo control, the drawing down position is more accurate and stable.

5.Color mark tracking

There are color marks on the film which on one bag and part to mark the length of the bag. Photoelectric sensor or encoder detect the color marks on the film then the cutter cut the bags with a correct position, at the same time the draw down will be drawing down the film. The Encoder with higher accurate then Photoelectric sensor.

6.Sealing jaws

For sealing bags.The horizontal sealing jaws seal the upper and lower edges of the bag, the vertical sealing jaws seal the back seal of the bag. Normally sealing methods have heat sealing, ultrasonic sealing, pulse sealing etc.

7.Cutter

The cutter is inserted in one of the horizontal sealing jaws,after filling,the cutter will cut the bags.The lower bag is finished bag, and the upper bag is unfilled without top sealed.

8.Bag type

Different vertical packaging machine can pack different bag types,like 3 sides sealing bag, 4 sides sealing bag, stick bag ,pillow bag, gusset bag, flat bottom bag, quad sealed bag, and so on.Contact with Tianjin Newidea Machinery co., Ltd.to get more details.

9.Nitrogen inflating function

The nitrogen inflating is optional function you can on this function by the touch screen.Their is a nitrogen tube connected to the bag forming tube,can Inflate nitrogen into the bag while filling products.

Inflating nitrogen to the bags can extend the food expiration also can protect fragile food broken.Flexible packaging machine packed bag shape can be easily changed and fold, so for some fragile food normally inflating gas to make bags.Especially for snack food nuts,puffed food.

10.PE film sealing jaws

This sealing jaws is professional designed for PE film sealing, adopt special temperature control structure to protect PE film no melting and ensure bag sealing firm.

11.Vacuum film drawing

Vacuum film drawing function suitable for frozen products, powder products to avoid pulling slip on the film. So makes the bag length and cut position very accurate.

12. Weighing system

The weighting system is on the top of the packaging machine ,connected to the filling port to the bag forming tube.It is for measuring the weight of the products. Granular products generally use single-head, two-head, four-head linear scales, as well as 10, 14,32 multi-head combined weighing scale,volume cups, etc. Powder products are generally used: screw measurement. Liquid and sauce are measured by cylinder pump or rotor pump.

12.Lifting system

Used for lifting and conveying the products from ground to the top of the weighing system. The equipment includes Z-type elevator, belt conveyor for granular products, screw elevator, vacuum feeder for powder products etc.

13.Finished product output system

Normally consist of finished product conveyor, and rotating collecting disk. They make your finished product output more orderly and convenient.

The above are some common terms for vertical packaging machine. I hope this article can be helpful to whom need a flexible packaging machine. To learn more about packaging machine knowledge, please pay attention on other articles from Tianjin Newidea Machinery CO., LTD